Technical Bulletins

To download any of our technical bulletins, click the "Download" button below the title.

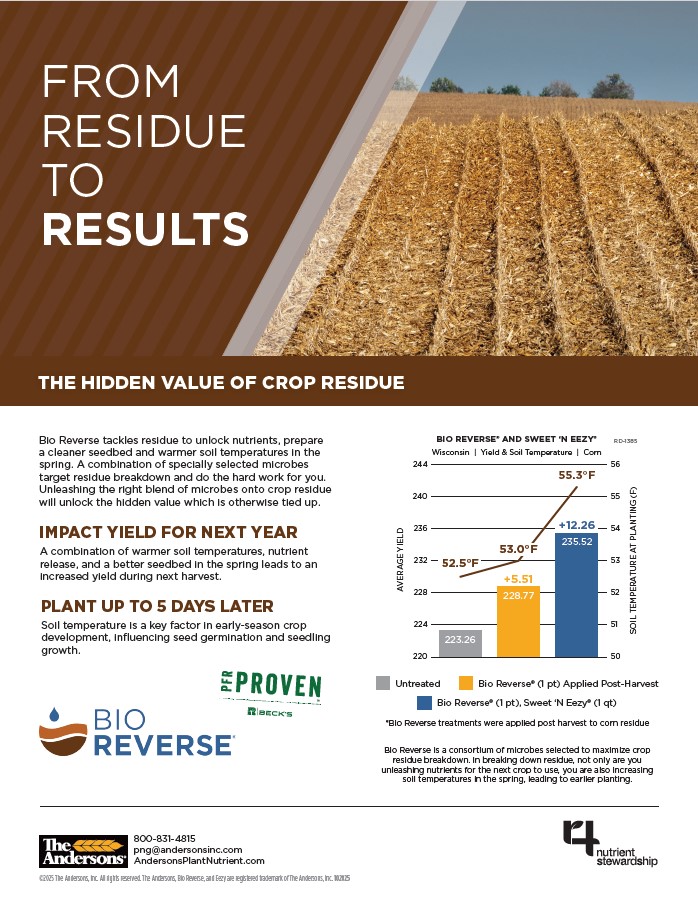

Residue Management

Residue Management

Hemp Fiber and Seed Production

Hemp Fiber and Seed Production

Hemp Cannabidiol (CBD) Oil Production

Hemp Cannabidiol (CBD) Oil Production

Organic Product Sales Sheet:

Organic Product Sales Sheet:

Nutrients for Organic Use

Technical Bulletin 01:

Technical Bulletin 01:

Alfalfa Foliar Research in Wisconsin

Technical Bulletin 02:

Technical Bulletin 02:

6-24-6 Outperforms Conventional Starters

Technical Bulletin 03:

Technical Bulletin 03:

Foliar Applied Diamond 9-18-9 Increases Soybean Yields

Technical Bulletin 04:

Technical Bulletin 04:

PureGrade® Foliar Fertilizer Boosts Crop Potential

Technical Bulletin 05:

Technical Bulletin 05:

Low-Salt Foliar Program | Corn

Technical Bulletin 06:

Technical Bulletin 06:

Low-Salt Foliar Application Boosts Soybean and Alfalfa Yields

Technical Bulletin 07:

Technical Bulletin 07:

Basics of Foliar Application

Technical Bulletin 08:

Technical Bulletin 08:

Benefits of Slow Release Nitrogen

Technical Bulletin 09:

Technical Bulletin 09:

Calculating Salt Index

Technical Bulletin 10:

Technical Bulletin 10:

A Review of Strip-Till and Nutrient Banding

Technical Bulletin 11:

Technical Bulletin 11:

The Salt Index of Fertilizer is More Important Than Ever

Technical Bulletin 12:

Technical Bulletin 12:

Orthophosphate vs. Polyphosphate

Technical Bulletin 13:

Technical Bulletin 13:

Urea Reaction in the Soil

Technical Bulletin 63:

Technical Bulletin 63:

Managing Fertilizer Application for Profit

Technical Bulletin 68:

Technical Bulletin 68:

Check Planter's Liquid Starter Equipment Before Heading to the Field

Technical Bulletin 69:

Technical Bulletin 69:

Soil Tests Offer Guidance

Technical Bulletin 71:

Technical Bulletin 71:

First Roots Need Nutrients Fast

Technical Bulletin 79:

Technical Bulletin 79:

Managing Risk with Split-Applications

Technical Bulletin 80:

Technical Bulletin 80:

Increasing Irrigation Efficiency

Technical Bulletin 82:

Technical Bulletin 82:

Tissue Test to Identify Nutrient Levels

Technical Bulletin 83:

Technical Bulletin 83:

Avoid Issues: Understand the Differences

in Polyphosphate Fertilizer Production

Labels, Product Sheets & SDS Documents

Labels, product sheets and safety data sheets are listed with each product in our product listings.

Product Comparison Sheets

To download any of our product comparison sheets, click the "Download" button below the title.

Boron Solutions

Boron Solutions

Download

Slow Release Nitrogen Products

Slow Release Nitrogen Products

Zinc Solutions

Zinc Solutions

PureGrade: GoldStart

PureGrade: GoldStart

PureGrade: Diamond

PureGrade: Diamond

PureGrade: Premium

PureGrade: Premium

Calcium Solutions for Specialty Crops

Calcium Solutions for Specialty Crops

Zinc Solutions for Specialty Crops

Zinc Solutions for Specialty Crops

Boron Solutions for Specialty Crops

Boron Solutions for Specialty Crops

A properly-timed nutrient management program is essential for maximizing yields at harvest. Both corn and soybeans have different nutrient needs at varying stages throughout the growing season. Understanding these critical growth stages and providing adequate nutrition to the growing crop is key to maximize crop productivity and achieve higher yields at harvest.

Click here to download The Andersons High Yield Programs for Corn and Soybeans.

Click here to download The Andersons High Yield Programs for Sugar Beets, Potatoes, and Sweet Corn.

How do I learn more?

Reach out to your Territory Manager from The Andersons.

Interested in becoming a Dealer or Distributor?

© 2020 The Andersons, Inc. All Rights Reserved.

Brochures and White Papers

To download any of our brochures, click the "Download" button below the title.

2021

Specialty Product Guide

Biological Solutions Brochure

2023 Research Trials

2022 Research Trials Brochure

2021 Research Trials Brochure

2020 Research Trials Brochure

2019 Research Trials Brochure

Resources

Below are some of the websites that we have found to be most beneficial to our customers.

Andersons Business Groups

Andersons Trade Group

Andersons Ethanol Group

Andersons Rail Group

Industry Information

4R Nutrient Stewardship

International Plant Nutrition Institute

Responsible Ag

Fluid Fertilizer Foundation

Crop Protection Chemicals

Corteva Agriscience

Bayer Crop Science

Syngenta

FMC

BASF

Seed

Asgrow and Dekalb

Pioneer

Credit and Loans

American Business Credit Farm Equipment Leasing and Loans

Farm Credit

Ag Credit

USDA Farm Loan Program

Precision Agriculture

Trimble

Ag Leader

Weather

The Weather Channel

Spraying

TeeJet

Enlist and Enlist Duo

XtendiMax

Engenia

FeXapan

EPA - Certified Pesticide Applicator Instructions

Agricultural Magazines

Progressive Farmer

Successful Farming

U.S. Farmer

No-Till Farmer

Farm Journal

Crops and Soils Magazine

Ag Web

Agricultural Universities

Michigan State University College of Agriculture and Natural Resources

Ohio State University Agronomic Crops Network

Purdue University Pest and Crop Newsletter

University of Illinois Extension

University of Nebraska - Lincoln Agricultural Research Division

Oklahoma State University Division of Agricultural Sciences and Natural Resources

University of Minnesota

Iowa State

University of Missouri

Government Agriculture Organizations

United States Department of Agriculture Farm Service Agency

United States Department of Agriculture

Natural Resources Conservation Service

National Association of State Departments of Agriculture

United Soybean Board

American Soybean Association

National Corn Growers Association

American Farm Bureau Federation

Analytical Labs

Waypoint Analytical

A&L Great Lakes

Midwest Laboratories

Ward Laboratories

Approved Tank Mix Partners

Learn more about The Andersons approved products for tank mixing with specific herbicides.

STORAGE AND CLEANING GUIDELINES FOR LOW-SALT FERTILIZER TANKS

Quality is the foundation of our products and manufacturing processes. We want to provide you with the highest-quality products to help grow your operation. To ensure the quality you expect, we focus on five key points during the manufacturing process:

- Pressing suppliers for the highest quality raw materials

- Refining manufacturing processes for maximum efficiency and environmental sustainability

- Implementing and maintaining quality management processes and systems

- Performing rigorous testing to ensure each product is manufactured to specifications

- Continuous evaluation and improvement of these processes

Quality management does not end once a product leaves our facility. Our customers play a key role in upholding quality. Once we have produced and shipped a product, it is in our dealers’ and distributors’ hands to maintain the product’s integrity until it reaches the field. To assist with this process, we have developed the following tank storage and cleaning guidelines.

We hope you find these guidelines useful. Thank you for trusting The Andersons to produce high-quality products that will help you reach your goals. Please contact us or your representative from The Andersons if you have questions or comments.

GENERAL STORAGE GUIDELINES FOR LOW-SALT FERTILIZERS

When storing low-salt fertilizers, follow these Dos and Don’ts:

CLEANING GUIDELINES

Safety Guidelines

Before starting any preparations or cleaning procedures, be sure to wear the proper personal protective equipment (PPE). Consult the product SDS for any additional PPE requirements or safety precautions. Follow these best practices:

1. Wear appropriate waterproof boots with good traction on the soles

2. Utilize safety goggles with face shield

3. Use chemical-resistant gloves

4. Wear appropriate head and body protection

Additional safety precautions:

1. Make sure the tank is free of all product up to the manway opening.

2. Be aware of the manway cover weight and use additional help when removing

bolts and the cover.

3. Isolate the tank and fill lines before opening manways. Make sure all fill valves are

closed and secured.

4. Follow the permit-required confined space entry protocol.

5. Test the air quality. Provide additional mechanical ventilation, if necessary.

6. Make sure all submersible pumps and electrical cords have an appropriate GFCI.

7. Be extra aware of heat exhaustion risk for personnel. Rotate entrants frequently.

8. Maintain control over the pressure washer trigger but do not tape or bypass the

trigger in the open position. Ensure appropriate pressure regulation.

9. Beware of carbon monoxide contamination. Make sure the pressure washer is

located outside the tank and away from the manway or ventilation intake.

Tank Cleaning Procedure

1. Remove all liquid from the tank.

2. Inspect the interior of the tank for solids. If solids are present, remove loose solids

and repurpose. You may use solids/sludge/rinsate to make suspensions or solid

fertilizers or apply to a field with a manure spreader using proper agronomic rates.

3. Before cleaning, spray the bottom to remove residue from the sump or cone. Use

of a pressure washer is recommended.

4. Starting from the top of the tank and working down, spray the roof and the inside

walls of the tank. Be cautious of trip/slip hazards caused by the hoses and slick

floor surface.

5. Once the tank has been washed from top to bottom, add enough water to avoid

starving the pump and recirculate for 10 minutes, if possible.

6. Use the system pump and drain the tank.

7. Repeat steps 2 through 6 two more times. If residue remains, use hot water and

detergent and rinse thoroughly.

8. Clean or replace screens and hoses.

9. Perform a final inspection to ensure the tank and hoses are clean and free of all

solids and liquids.

10. Allow the system to dry before filling with another product.

For questions, contact your Territory Manager from The Andersons.

Boron Solutions

Boron Solutions