Update from the Field: CBD A-OK

Posted by Dave Dyson, Agronomist on August 23, 2019

The agriculture industry is abuzz about hemp and the opportunities a new crop can provide to markets and crop rotations. Regardless of whether you think the 2018 Farm Bill went too far in legalizing the propagation and distribution of hemp, or if you think it did not go far enough, we need to figure out the most economical way to grow this emerging crop.

States have different laws enforcing this new crop, so I am not going to get into the legal weeds too much. The Farm Bill allows each state to license individual producers and starts the regulation process for 3 types of hemp production. You may notice I am using the word “hemp” instead of “marijuana”. The differences between the two crops are as big as corn and sorghum. Both plants look alike but produce different end products. Hemp is a broadleaf plant that has less than 0.3% THC. There are three products that can come from the hemp plant: seed, fiber, and cannabinoids.

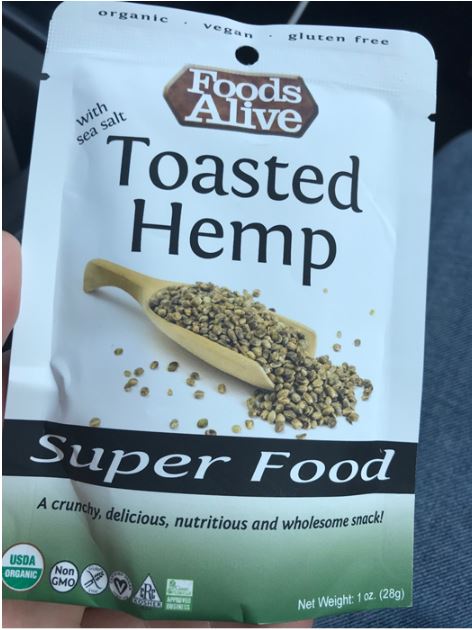

Seeds from the hemp plant look like BBs from a Red Ryder BB gun. The seeds can be dried and packaged for human consumption (figure 1) or can be crushed for cooking oil.

Figure 1: Hemp seeds can be used for human consumption; it is considered a super food!

The plants that are bred to produce seeds are short and both male and female plants will be planted in close proximity to each other (figure 2). Only the female plants will produce the seed, but the male plants are needed to produce the pollen. Planting hemp for seed or fiber is similar to planting alfalfa, 35-70 lb/ac at a ¼ inch depth. Soil crusting is a major issue during emergence. The seeds will be harvested using a grain platform head and caution will be needed as the seeds can easily shatter.

Figure 2: The Andersons' employees Jessica Link and Matt Gasaway inspect a female hemp plant designed to produce seed at Purdue University’s Hemp Field Day south of West Lafayette, IN. The male plants are lighter colored with pollen sacks shown in the background.

Fiber from the hemp plant is durable and lightweight, making it a sought after commodity in the automobile industry. All side panels in Volkswagen and Cadillac automobiles are backed with hemp fiber. Unfortunately, hemp fiber has to be imported because the demand is outpacing U.S. production. The hemp plants used in fiber production grow 6-7 feet tall (figure 3). Planting hemp for fiber is similar to hemp seed production. A producer growing hemp for fiber will let the plant start to bloom and then cut the crop just like an alfalfa crop.

Figure 3: Account Representative Matt Gasaway and Purdue Student Wyatt Dyson inspect hemp grown for fiber production. As you can see, this plant gets very tall.

CBD is the abbreviation for cannabidiol, one of the many cannabinoids or chemical compounds found in marijuana and hemp. You may be familiar with THC, another compound found in the cannabis plant. However, unlike THC, CBD is not psychoactive. CBD production plants are short, similar to the seed production plants (figure 4). Female plants will be planted every 4-5 feet for CBD production; these plants will either be a clone or seedlings. Male plants need to be separated from the females. If the female plant never receives pollen from the male plant, their blooms will keep growing. The pollen from a male plant can travel up to 7 miles. The bloom is where the CBD chemical is most concentrated; the bigger the bloom, the more CBD chemical the producer can harvest. Planting and harvest is done by hand, making CBD production costly.

Figure 4: Agronomist David Dyson inspects a hemp plant grown for the CBD oil.

In conclusion, a hemp crop can be a real cash crop for a producer willing to go through the licensing process. Gross estimates are as high as $25,000/ac for a CBD crop. This would be a great rotational option if you are a tomato and/or melon grower. No pesticides are labeled for use post-emergence on hemp yet. If you have questions about hemp production or need fertility recommendations, contact me at (574) 626-2522 or david_dyson@andersonsinc.com.

FOR MORE INFORMATION:

Please complete the form, and we’ll get you in touch with your Territory Manager from The Andersons.

Dave Dyson is a regional agronomist for The Andersons’ Farm Centers which are located throughout Ohio, Michigan, and Indiana. He is an Indiana native and grew up on a dairy farm in Miami County. A graduate of Purdue University with a degree in Crop & Soil Science, Dave has a deep knowledge of various agronomic topics and is committed to helping growers improve their crops. If you have any questions, Dave can be reached at david_dyson@andersonsinc.com.