Agronomy Update September 2019

Posted by Dave Dyson, Agronomist on September 13, 2019

MANAGEMENT

By Dave Dyson, Agronomist

Crop residue, or “trash”, can be a major source of problems for farmers in the spring during planting. Corn stalks can especially cause havoc to planters or drills. The excess cellulose and stalk residue can puncture tires, create voids in the seed trench, restrict soil-to-seed contact, hamper groundwork, and be destructive to machinery. Crop residue causes issues with next year’s seedbed, and it can also tie up nutrients that may not be released until after the crop’s needs are satisfied. Applying a residue treatment will accelerate the breakdown of crop residue and release the nutrients contained in the residue.

UltraMate® LQ liquid humate incorporates all of the above benefits for residue management and does not require an additional trip across the field. The Andersons is engaged in a multi-year study of mixing UltraMate LQ, 28% UAN, and fall herbicides together and applying that mixture on residue in the fall (Figure 1). Most growers already apply a fall burndown on their corn stalks or soybean residue, so incorporating a stalk degradation agent into the tank mix will maximize the trip across the field. The UltraMate LQ and 28% UAN will encourage the microbial population to increase and accelerate residue breakdown, releasing the stored nutrients which they contain.

Figure 1: Product sheet for UltraMate LQ used for residue management

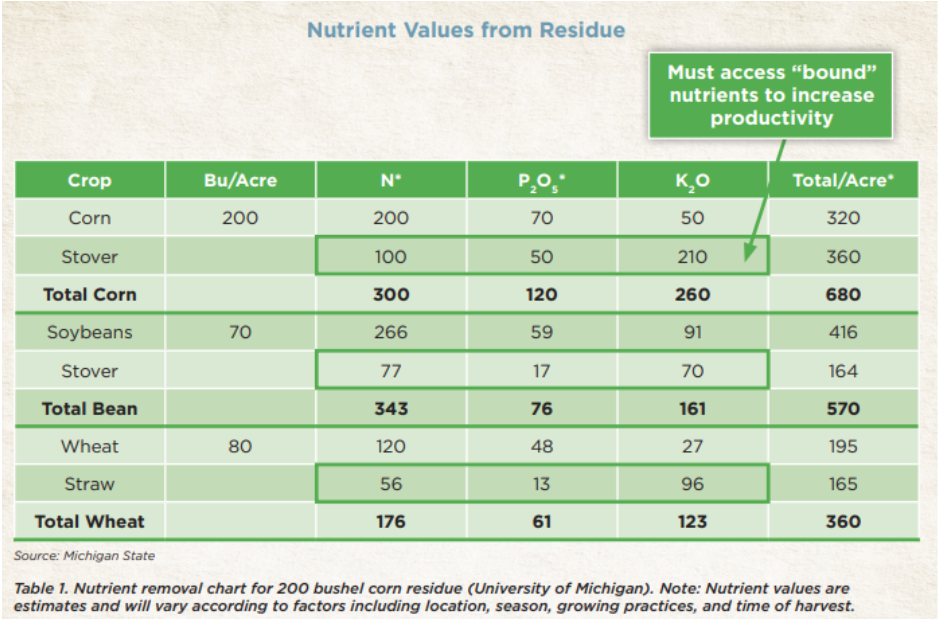

Stalk residue retains valuable nutrients, but they are locked up and inaccessible by growing crops. Once soil microorganisms break down the residue, critical nutrients are released to the soil and available to the growing crop. This is a natural process that occurs slowly, usually taking around three years to break down corn stalks. When UltraMate LQ is applied, the process of stalk degradation is accelerated, releasing nutrients for next year’s crop. The fertilizer value of crop residue is well-documented and can be easily calculated per ton of stover (Figure 2). The nutrient content of every ton of corn residue can be up to 4 lbs of P2O5, 22 lbs of K2O, and 1 lb of sulfur.

Figure 2: Estimated nutrient removal chart for 200 bu/acre corn residue from the University of Michigan.

In conclusion, the application of UltraMate LQ following harvest will help accelerate the degradation of crop residue. As shown in Figure 3, the residue treated with UltraMate LQ and 28% turned black and started to degrade faster than the untreated check. UltraMate LQ can be applied with fall herbicides to avoid an additional trip across the field. This will help with equipment maintenance and planting preparation, and it will also increase the availability of nutrients that are normally tied up in the stover. Contact your representative from The Andersons for additional product information and rate recommendations.

Take Away Bullets:

- Add UltraMate LQ at 1gal/ac and 28% UAN at 3gal/ac to crop residue.

- Breaking down stover will release nutrients for next year’s crop.

- Reducing residue will provide a smooth, efficient planting pass next spring.

Figure 3: UltraMate LQ at 1gal/ac and 28% at 3 gal/ac was applied to the left. Untreated check is shown on the right.

RESEARCH

By Jessica Stacy, Product Specialist

The research below illustrates the difference the fall application of a residue management product can make on yields.

A 2015 residue management study revealed a 6 bu/A increase in soybean yield on corn stalk acres receiving an application of 28% UAN and UltraMate LQ.

Treatments were applied to corn stalks the previous fall, allowing for nutrient release and a better seed bed. The carbon in UltraMate LQ liquid humate helped to stabilize the 28% UAN application, and jumpstarted microbial activity to degrade corn fodder. The study took place in Walton, IN.

FOR MORE INFORMATION:

Please complete the form, and we’ll get you in touch with your Territory Manager from The Andersons.

©2019 The Andersons, Inc. All rights reserved. UltraMate LQ is a registered trademark of The Andersons, Inc.